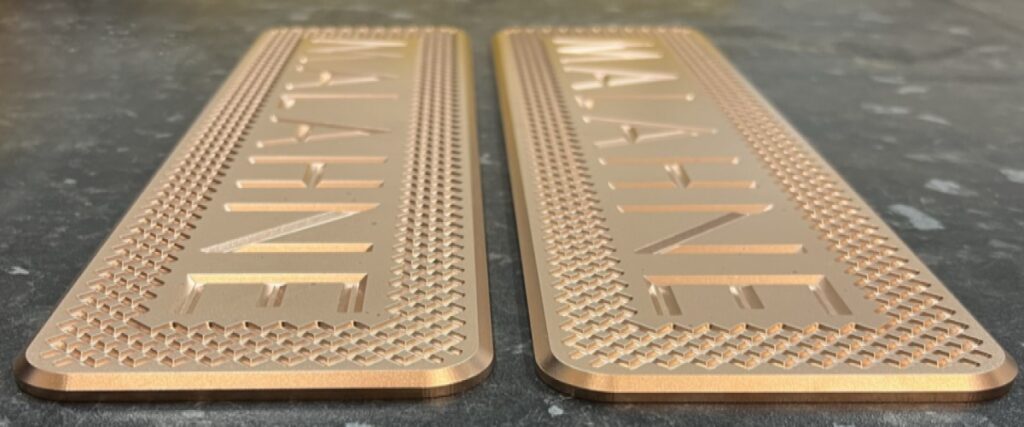

Boat and ship registration plates

Boat and ship registration plates manufactured to order in high quality. Safire offers boat and ship registration plates to order. High-quality engravings that will last the test of time! Boat and ship registration plate engraving service at Safire in Southampton, England To see more samples of engraved work by Safire for plaques, nameplates, signs, etc.. […]

Detailing a variety of items and products with engraving

High-quality detailing of items and products with engravings by Safire. Safire offers full design and detailing solutions. High-quality detailing and engravings that are only limited by your budget! Detailing engraving service at Safire engraving in Southampton To see more samples of engraved work by Safire for plaques, nameplates, signs, etc.. see here: What can we […]

Deep bronze engraving

Deep high-quality bronze engravings by Safire. Deep bronze engraving custom-made & engraved to order. Deep bronze engraving service at Safire Utilizing our creative flair we will work on your designs or we can design for you to suit your project plans. Safire works to high standards and can produce signage that you will love and […]

Bronze plaque modified and updated

An old bronze plaque was modified and detail engraved by Safire. To see more samples of engraved work by Safire for plaques, nameplates, signs, etc.. see here: What can we do for you?

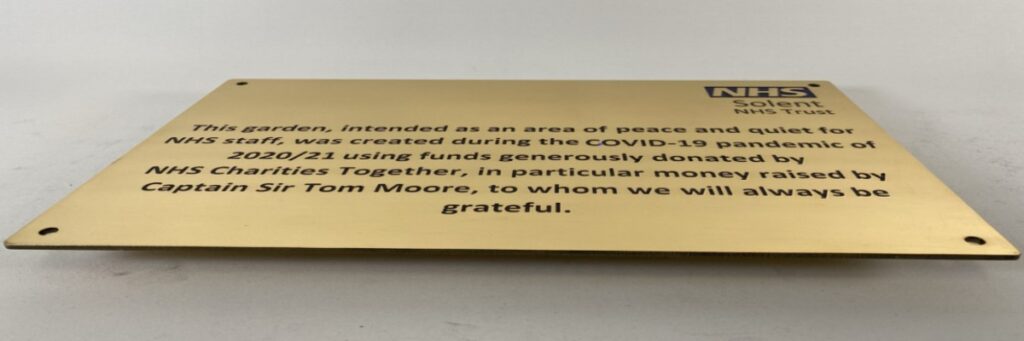

Brass plaques and name plates engraved to order

High-quality and detailed brass engravings by Safire. Brass engraving service at Safire To see more samples of engraved work by Safire for plaques, nameplates, signs, etc.. see here: What can we do for you?

High quality brass engravings in Southampton

High quality brass engravings in Southampton Safire offer high quality brass engravings from their workshop in Southampton.We can engrave anything from a simple number or letter to a full custom designed name plate plaque. Engraved brass name plate plaques Brass is a high quality material that can be engraved and machined and finished to a […]

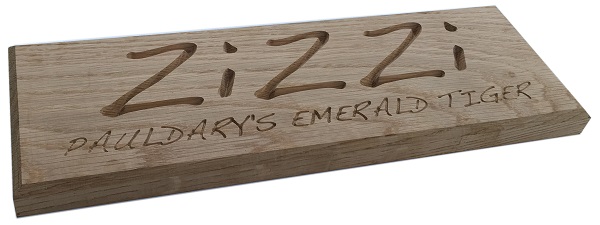

Wooden nameplates made to order from oak and teak in southamton

Wooden oak name plates made to order in southampton Custom made oak name plates made to order in Southampton. The Zizzi wooden name plate plaque shown on this page was made for a customers horse stable. You can see we used a deep V carving engraving process for the main name and the detailed text […]

316 marine grade stainless steel and black acetal plastic subsea ROV sampling clamps

316 marine grade stainless steel and black acetal plastic subsea sampling clamps ROV Parts machined from 316 marine grade stainless steel plate and black acetal plastic plate. Plastic and Stainless machined parts made to fit together These parts were part of marine life collection device that took marine samples from the seabed via a remote […]

Stainless steel angle and waterjet cut parts milling machined

Stainless steel angle and waterjet cut parts milling machined Waterjet cut and angle parts machined in 316 grade stainless steel These 316 marine grade stainless steel parts have been cut from raw stock then machined into the final parts for a Sub sea ROV sensor jig / rig. The angles were sawn from standard 30mm […]

Thick grey PVC component parts machined on a cnc milling machine and a cnc lathe

Thick grey PVC component parts machined on a cnc milling machine and a cnc lathe These Grey PVC parts were turned on our CNC lathe and milled on out CNC milling machine Plastic Machining A selection of grey PVC parts that were for SUB sea ROV sensors, all parts were machined in grey PVC. They […]