Machining Services Southampton

Safire can supply your machined parts

Safire Associates machining services include:

Machined parts

in any quantity

Whether you require a small batch of parts or a large quantity…

Safire can supply your machined parts.

One off parts

machined to order

One off machined parts can be produced to order from simple to complex and to your design

Small Job

Shop

With our small job shop, we can accomodate small machining jobs

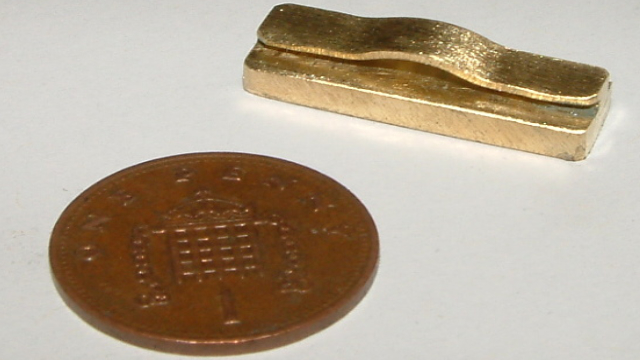

Micro Machining

of small parts

When you want really small parts, Safire can Micro machine them

Safire has been offering machining services from Southampton since the early 1990’s, offering accurate machined parts to high standards and great quality.

In addition to being able to supply CNC machined parts in small to large batches, Safire also offer general machining and the manufacturing of one off’s, proto-type parts, and repairs as well as batches of parts, all produced with high attention to detail.

Safire machining services

In conjunction with our associates, we have access to a full selection of machining processes.

Utilising both manual and CNC controlled that can be programmed by cad/cam or at the controllers of the machines. Coupled with the ability to design parts using the latest 3d cad software and program via cad/cam software.

Enabling us to tackle a wide and diverse range of work.

When you want really good quality parts and great service contact Safire.

We do not compromise on quality or service, so unfortunatly we do not offer cheap parts, nor will we promise you parts yesterday.

We will simply offer you good parts and we will try to deliver within a reasonable time period

We are professional, highly skilled engineers whom take the time to ensure a job is done well, with this in mind you can be assured your work will be completed to a high standard and good accuracy.

Machining services

- Cnc Machining

- Milling

- Turning

- Drilling

- Tapping

- Thread turning

- Thread milling

- Cad / Cam programming

Safire supply a wide range of machining services in conjunction with our associates utilising all the latest machining technologies.