Waterjet cutting at Safire

Our waterjet cutting service is based here in our Engineering workshop at Saxon wharf in Southampton. Uses very high-pressure water mixed with abrasive to cut almost any two-dimensional shape from virtually any material. We have a cutting area of up to 2440mm x 1220mm.

Also we can cut thicknesses from around 0.1mm to upwards of 125mm thickness (material dependant). We are waterjet cutting specialist’s and engineers and we adopt an engineering mindset with our waterjet cutting facilities ensuring the care and attention required when working on specials and hard to cut projects.

Waterjet cutting is a great cold cutting process furthermore it enables us to be creative too!

Corten steel fountain base waterjet cut from 6mm plate

Corten steel, often used in architectural, sculptural, garden design and other outdoor design projects.

As an example in this design for a private garden we waterjet cut over 4000 petal shaped holes.

As there is no heat created in the cutting process designs like this are perfect for waterjet cutting. Which you would not get with other forms of cutting e.g. laser cutting. Also due to the cold cutting process, the material is unaffected during the cut by the process. Meaning designs like this with many holes close together cut well. Also, there is minimal post finishing required with minimal burrs from the waterjet cutting process.

Safire Waterjet cutting specialists offer the precision water jet cutting of virtually any material. In general, the accuracy in cut is excellent (depending on material being cut), Also as waterjet cutting is an erosion process the range of materials that can be water jet cut is vast. Only ever limited by the materials own characteristics.

Materials that can be water jet cut include:

stainless steel, steel, aluminum, titanium, inconel, spring steel, copper, brass, bronze, armour / ballistic plate, UHMWPE Laminate, ceramics, porcelain, glass, glass mirror, fused glass, concrete, natural stone, plastics, pvc, acrylic, rubber, polyurethane, tufnol, G10 laminate, Fr4 laminate, high density polyethylene, polypropylene, acetal, HDPE, phenolic resin, plywood, mdf, hardboard, lino, foam, carbon fibre, felt, felt fur, ferrite, polystyrene and much more.

We can waterjet cut mixed materials of various thicknesses and qualities. In particular reflective, fragile, soft, hard materials and even hardened tool steels. Also, with no heat affected zone (HAZ). Which means materials like hardened tool steels can be cut, and due to the cold cutting process there is no change to the materials structure or form also without effecting the hardness of the material.

A small selection of small and thin parts

Small and thin parts

This is a collection of small and thin parts. Ranging in thickness from 0.05mm thick shim and 0.1mm thick copper to 1.2mm thick brass and aluminium.

Small and thin parts can be especially very tricky to cut using high pressure water jet. But In comparison to other processes like laser, waterjet is the only way to cut some parts. We have found ways to do this and these parts shown together with a £1 coin in the centre to give a sense of scale. Are a good demonstration of very small and thin parts we have cut.

Thick parts cut in many materials

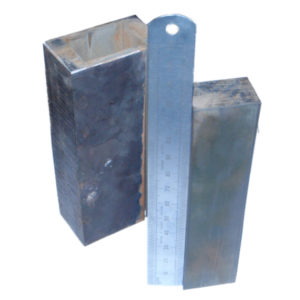

Thick parts

The centre core was water jet cut from this 125mm high hard En24t Steel block. We cut the rectangle part out from the centre. Shown here as an example with a steel rule placed by its side. We water jet cut this core out using our dynamic cutting head in this case to keep the cut as straight as possible. Subsequently leaving a nice rectangle hole through the centre of the block after removing the cut part.

EN24T steel is a very hard steel but we cut through it with our abrasive water jet and consequently without effecting the state of the materials hardness.

Larger parts profiled from plate

Large sized parts water jet cut..

On the waterjet machine we have an actual cutting area of 2440mm x 1220mm. We also have tricks to enable us to go over this size sometimes depending on the job in hand.

For example the gear wheel pictured is 1200mm diameter. From a set of old worn drive gears regularly used on a water sluice. Using 8mm thick steel Plate we waterjet a new set of cogs. There were no drawings to go by. In this case we reverse engineered from an old rusty worn one

Pictured above is a small selection of sample materials which we have cut

From the top Row 1:

19mm Aluminium plate, 9mm soft Foam, 40mm Steel, 45mm Soft wood, 6mm acrylic, 0.8mm copper, 1.5mm brass

From the top Row 2:

3.5mm Hardboard, 12mm porcelain, 18mm plywood, 1.5mm Stainless steel, 6mm alley tread plate, 10mm steel, 0.5mm stainless steel

From the top Row 3:

1.2mm Galvanised Steel, 6.5mm copper, 10mm brass, 6mm acrylic, 8mm glass feature tile, 0.9mm expanded steel mesh, 7mm ceramic tile

From the top Row 4:

3mm poly carbonate, 0.05mm Zinc foil, 6mm stainless steel, 10mm hard ceramic tile, 9mm rubber, 10mm MDF wood, 2.4mm FR4 Laminate