Safire Associates, Unit 008, Solent Business Centre, 343 Millbrook road, Southampton, SO15 0HW

Copyright 2024 © All rights Reserved. Design by Safire

Forecourt tank lids need modification when the tank is being upgraded, repaired or during tank re-lining operations.

In this case the tank lid was being converted from a 3″ BSP pipe fitting to a 4″ pipe fitting.

We basically removed the central 3″ BSP pipe and fitting, then prepared and fitted a new 4″ BSP female socket connection.

The process is described below.

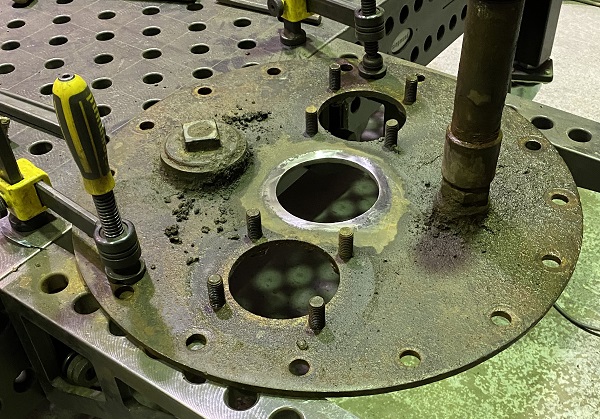

After some preparation work, we jigged the tank lid up on our watrjet machine, we then waterjet cut a new hole in the centre to take the new 4″ bsp fitting.

By using the waterjet not only did it finally remove the old welded Pipe from the centre but we were also left with a precision cut hole so the new 4″ BSP female socket would snugly fit in the hole.

The tank lids are normally very dirty and rusty, so we clean the weld area back to fresh bare steel and weld prep the joint on both sides.

We use a standard 4″ bspp female socket and the 4″ stainless steel fitting is machined to size on a lathe.

The machined 4″ bsp fitting is then fitted into the snug fitting hole and tig welded this shows the tig weld from the back

This shows the tig weld from the front, we have to carefully tig weld whilst also trying to avoid all the protruding parts and fittings still on the tank lid.

and the finished job, 3 tank lids with their new fittings ready to be grit blasted. painted and re-fitted to the tanks.

E7910